Products

-

Patented Product JBG-50 Rebar Thread Rolling Machine for 12-50mm Rebar

JBG-50 Rebar Thread Rolling Machine is especially fit for long rebar thread processing and large diameter rebar in bridge and tunnel. It can make threads on 12-50mm size rebar and max thread length could reach 120mm.

-

steel angle cutting machine steel rebar cutter steel round bar cutting machine

GQ40/GQ50/GQ60 rebar cutting machine is an ideal equipment for cutting. It can be applied to cut the normal

carbon steel rod, hot rolled steel, deformed bar, flat steel, square steel and angle steel in machine processing and construction projects. -

Fully Automatic JBG-40 Rebar Thread Rolling Machine for 16-40mm Rebar

JBG-40B Rebar Thread Rolling Machine is fully automatic, put the rebar in the correct position, just step on the foot switch, the entire machining process of clamping and thread rolling can be finished itselt.

It can make threads on 16-40mm rebar and max thread length could reach 100mm.

-

rebar bending machine factory direct sale steel rebar bending machine iron bending machines price

GW40 REBAR BENDING MACINE has reasonable design, simple structure. It can bend steel rod diameter to any required shape applying

to bridge, tunnel and many construction projects.

Advantages: 1. Low labor intensity, high work efficiency.

2. One time programming, it can bend 1-10 angles, also can automatically switch all angles set by the program.

3. The angle can be adjusted discretionarily (1 -350 degree), the angle is accurate, and the tolerance is less than ±1.

4. Single foot pedal, only one button operation, easy and fast operation, less time and effort.

5.Starting point control accuracy, large spring rest tolerance is less than ±0.5. -

stirrup spiral bender rebar rod circle bending machine steel rod arc bending machine

GWH series rebar arc bending machine is a special equipment of bending for large construction projects, bridges, tunnels, culverts, power stations, subway projects. It has advanced design, simple operation, safe and reliable, low labor intensity and high working efficiency.

-

rebar cutter machine reinforcement steel bar cutting machines

GQ40/GQ50/GQ60 rebar cutting machine is an ideal equipment for cutting. It can be applied to cut the normal

carbon steel rod, hot rolled steel, deformed bar, flat steel, square steel and angle steel in machine processing and construction projects. -

High speed iron rod rebar cutter machine

GQ40/GQ50/GQ60 rebar cutting machine is an ideal equipment for cutting. It can be applied to cut the normal

carbon steel rod, hot rolled steel, deformed bar, flat steel, square steel and angle steel in machine processing and construction projects. -

rebar thread cutting machine steel cutter

AQ40 rebar thread cutting machine

Machine Function

Rebar thread chaser machine is suitable for rebar threading after rebar upsetting. It can process straight threads of steel bars with specifications of M18-M45. It fits for HRB400, HRB500 rebar process, for other rebar models, need to check its tensile strength and yield strength.Machine Advantages

It can automatically complete the rebar threading by clamping rebar in one operation, and the processing speed is fast.

This machine adopts semi-automatic control, and the transmission is mechanical.

It has features of simple structure, convenient and reliable operation, and easy to learn.

Rebar thread chaser machine head has unique tool automatic opening and closing mechanism,

one time feed can complete the process, no need to shutdown manually, so greatly improving work efficiency.The unique tool automatic opening and closing mechanism of this machine head can achieve a one-time feed to complete the processing, without the need for manual shutdown, greatly improving processing efficiency.

It is equipped with a synchronous fine adjustment mechanism for four comb knives, which can meet the dimensional requirements of six levels of precision for steel bar threads.

When each processing cycle is completed, the head returns to the start position automatically, and the main motor automatically shuts down after powering off.

Once the next processing cycle starts, the machine head will leave the start position automatically, and the rotation will be started automatically,

the operating procedures is simple, safe and efficient.Machine Parameters

Model

AQ40

Suitable for Rebar Diameter

Φ16 – Φ40mm

MAX Thread Length

100mm

Cutting Thread Angle

60°

Chaser Thread Pitch(mm)

2.0P for 16mm;

2.5P for 18,20,22mm;

3.0P for 25,28,32mm;

3.5P for 36,40mm.

Rated Power

5.5KW

Voltage

3-380V 50Hz or others

Rotated Speed

40r/min

Oil Pump Flow

15L/min

Weight

765kg

Dimension

1720*700*1120mm

Machine Spare Parts

For one size rebar, need one set chaser, one set chaser has 4 pieces.

FAQ

Q1:What is the machine motor ?

A1:The machine motor is 3-380V-50HZ. but we also change it to 3-220V-60HZ, 3-415V-50HZ, 3-440V-60HZ, etc.

Q1: What is the machine spare parts?

A1: The machine spare parts is chaser.

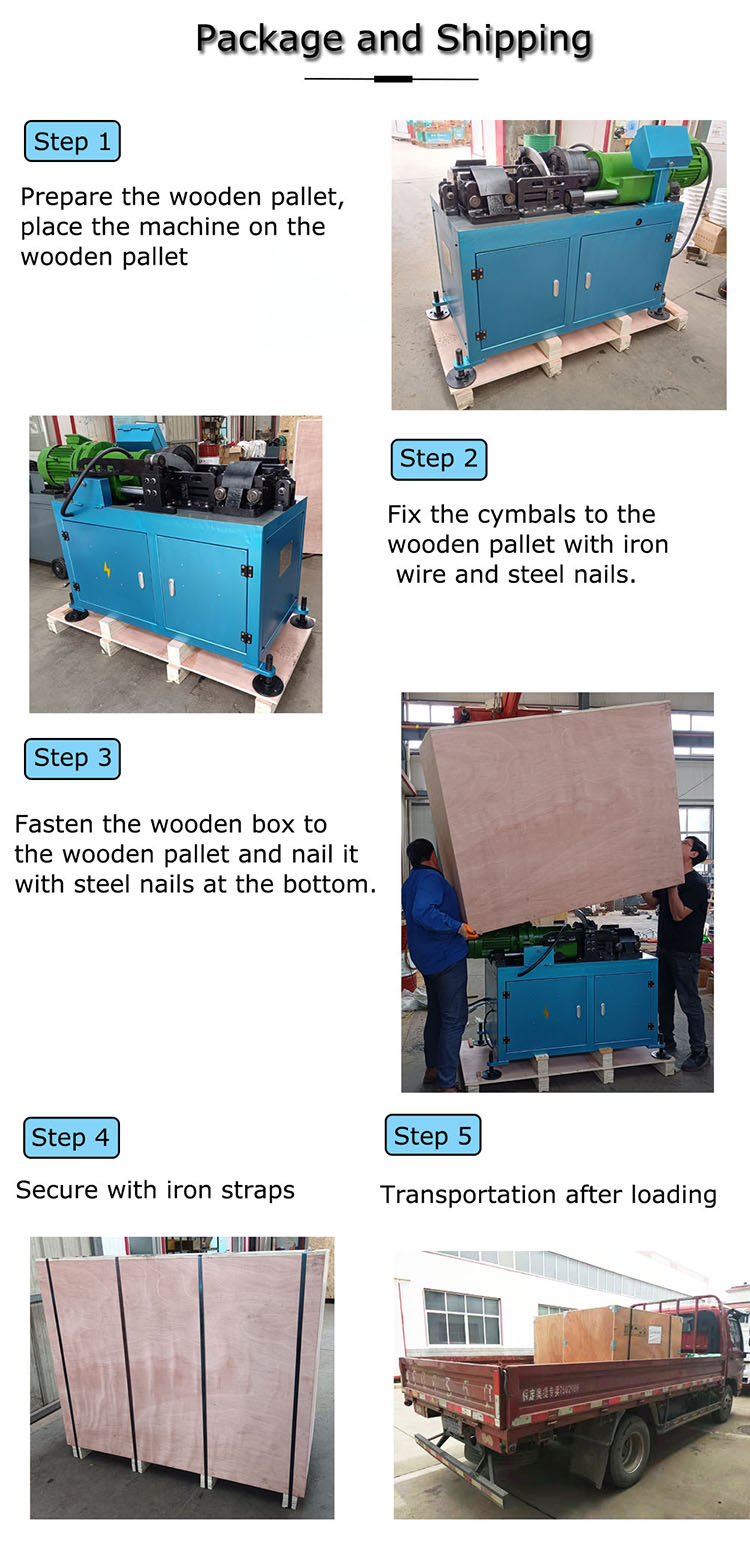

each size rebar needs one chaser.Package and Shipping

The machine is packed with plywood case.Customer Photos

-

Good Performance JBG-40KI Rebar Thread Rolling Machine with Famous Brand Motor

JBG-40KI Rebar Thread Rolling Machine adopts Chinese famous brand motor and reducer, machine performance is superior. It can make straight thread on 14-40mm rebar and max thread length is 65mm. JBG-40KI is updated version of JBG-40K, much more easier to operate and thread precision is more higher.

-

Reinforcing steel rebar upsetting machine

16-40 model Double Cylinder Rebar Upsetting Forging Machine

Machine Function

16-40 model Double Cylinder Rebar Upsetting Forging machine is mainly used for upsetting 16-40 diameter rebar, increase the diameter of rebar, make rebar end enlarged, in order to make the effective section is larger than the original steel.

Such as for 25mm rebar, after upsetting, it is become 28mm.

Then you can use rebar thread rolling machine or rebar thread cutting machine to get rebar threads, connect with rebar.Machine Advantages

After upsetting by 16-40 model Double Cylinder Rebar Upsetting Forging machine, its tensile strength is larger than original rebar itself.

This machine is applicable to the reinforcement connection of national key projects with high requirements such as bridges and subways, and is not affected by environmental factors.

Machine Parameters

Model

16-32

16-40

Processing Range

Φ16 – Φ32mm

Φ16 – Φ40mm

Upsetting Length

3-5cm

3-5cm

Motor Power

7.5KW

11KW

Rated Voltage

3 – 380V – 50HZ or others

3 – 380V – 50HZ or others

Working Efficiency

3-5 seconds / piece

3-5 seconds / piece

Capacity of Tank

115L

165L

Oil Pump Flow

15L/min

15L/min

Hydraulic Oil Pump

31.5Mpa (10MCY 14-1B)

31.5Mpa (10MCY 14-1B)

Hydraulic Oil

68# Antiwear

68# Antiwear

Working Stroke of Cylinder

150mm

150mm

Weight

1000KG

1300KG

Dimension

1250*850*1650mm

1340*990*1800mm

Machine Spare Parts

For one size rebar, need one mould, one set mould has 2 pieces.

FAQ

Q1:What is the machine motor ?

A1:The machine motor is 3-380V-50HZ. but we also change it to 3-220V-60HZ, 3-415V-50HZ, 3-440V-60HZ, etc.

Q1: What is the rebar diameter after upsetting?

A1: After upsetting, the rebar diameter will become bigger. For instance, after upsetting the 25mm rebar will become 28mm. But if you have other special requirement, we also can customize mould for you. Q1: What is the machine spare parts?A1: The machine spare parts is mould. each size rebar needs one mould.

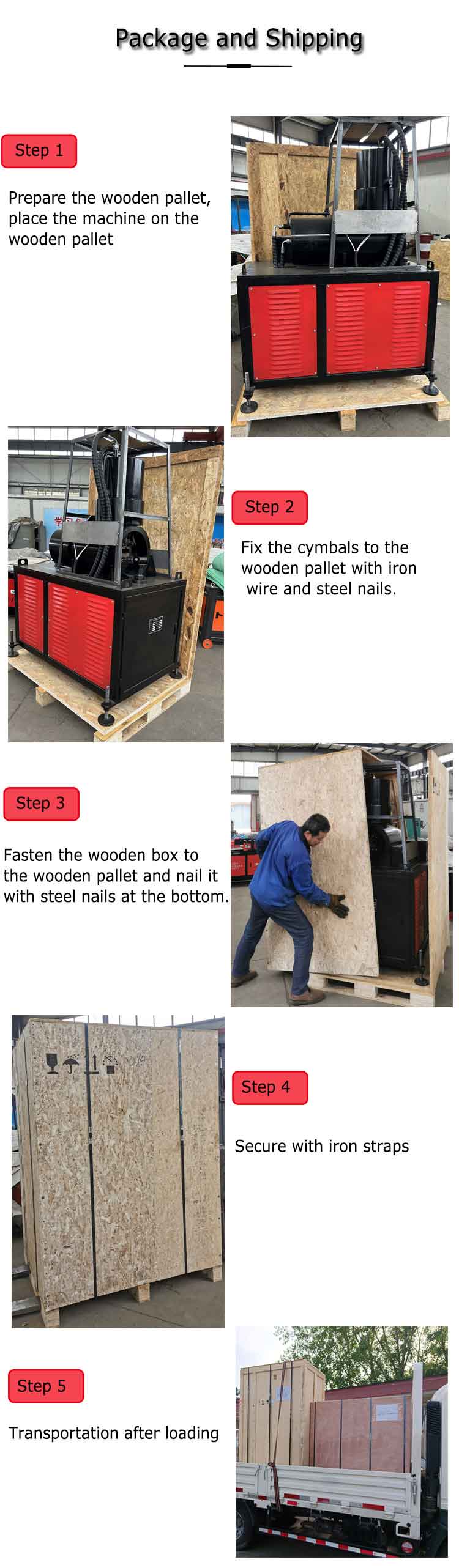

Package and Shipping

The machine is packed with plywood case.Customer Photos

-

rebar upsetting machine for construction

Rebar Forging Machine is a type of equipment used for enlarging ends of rebars.

16-32 model Double Cylinder Rebar Upsetting Forging Machine

Machine Function

16-32 model Double Cylinder Rebar Upsetting Forging machine is mainly used for upsetting 16-32 diameter rebar, increase the diameter of rebar, make rebar end enlarged, in order to make the effective section is larger than the original steel.

Such as for 25mm rebar, after upsetting, it is become 28mm.

Then you can use rebar thread rolling machine or rebar thread cutting machine to get rebar threads, connect with rebar.Machine Advantages

After upsetting by 16-32 model Double Cylinder Rebar Upsetting Forging machine, its tensile strength is larger than original rebar itself. This machine is applicable to the reinforcement connection of national key projects with high requirements such as bridges and subways, and is not affected by environmental factors.

Machine Parameters

Model

16-32

16-40

Processing Range

Φ16 – Φ32mm

Φ16 – Φ40mm

Upsetting Length

3-5cm

3-5cm

Motor Power

7.5KW

11KW

Rated Voltage

3 – 380V – 50HZ or others

3 – 380V – 50HZ or others

Working Efficiency

3-5 seconds / piece

3-5 seconds / piece

Capacity of Tank

115L

165L

Oil Pump Flow

15L/min

15L/min

Hydraulic Oil Pump

31.5Mpa (10MCY 14-1B)

31.5Mpa (10MCY 14-1B)

Hydraulic Oil

68# Antiwear

68# Antiwear

Working Stroke of Cylinder

150mm

150mm

Weight

1000KG

1300KG

Dimension

1250*850*1650mm

1340*990*1800mm

Machine Spare Parts

For one size rebar, need one mould, one set mould has 2 pieces.

FAQ

Q1:What is the machine motor ?

A1:The machine motor is 3-380V-50HZ. but we also change it to 3-220V-60HZ, 3-415V-50HZ, 3-440V-60HZ, etc.

Q1: What is the rebar diameter after upsetting?

A1: After upsetting, the rebar diameter will become bigger. For instance, after upsetting the 25mm rebar will become 28mm. But if you have other special requirement, we also can customize mould for you. Q1: What is the machine spare parts?

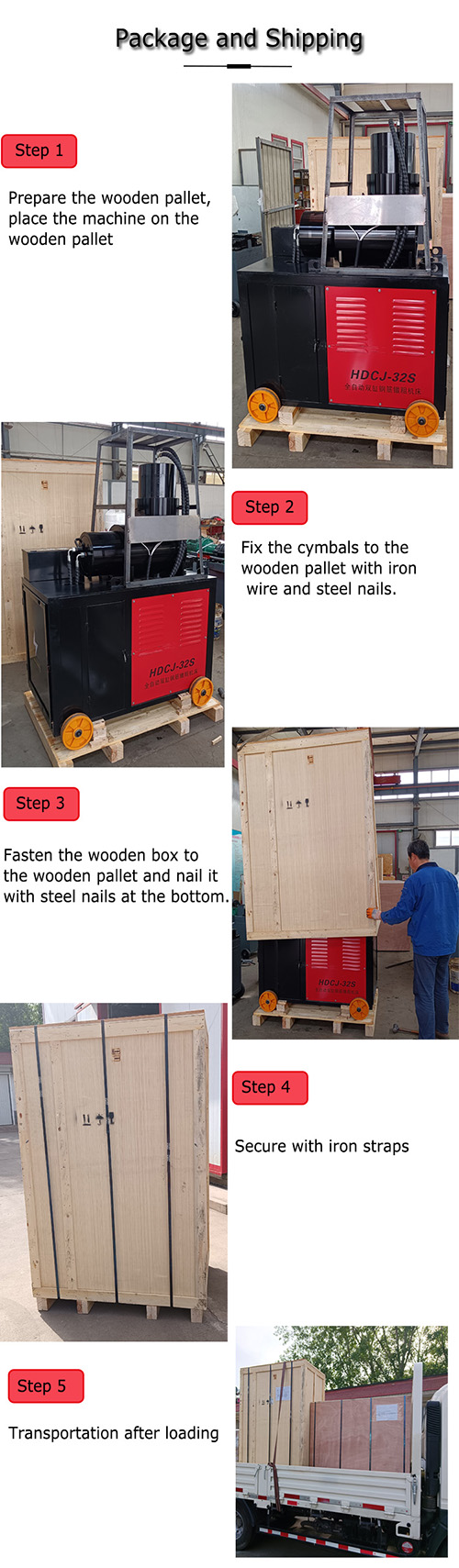

A1: The machine spare parts is mould. each size rebar needs one mould.Package and Shipping

The machine is packed with plywood case.Customer Photos

-

Factory Direct Price Rebar Cold Extrusion Press Machine For Sale cold extrusion machine

JYJ-32 Model Rebar Cold Extrusion MachineMachine Function

It is used to extrusion coupler, in order to let coupler bite with rebar tightly.

Through squeezing force the rebar coupler become plastic deformation, then it can bite tightly with ribbed steel bars. It has hydraulic pumping station, electric motors, valves, fuel tank, electric motors, hydraulic pumps, valves, fuel tanks, and pressing die.

Machine Features

1. Ultra-high-pressure oil pump: powerful and vigorous, reducing working time.

2. Premium hydraulic pressure pliers: 60 MPa is easy to extrude, the extrusion result is good, and it is durable and not easy to form.

3. The pressure gauge shows: the pressure of the machine can be controlled at any time, and it is convenient to squeeze and release the pressure.

4. Dynamic pressure mould, constant pressure mould, reasonable design, excellent materials.Machine Parameters

Model

JYJ-32

JYJ-40

Crimp Size

Φ12 – Φ32mm

Φ12 – Φ40mm

Rated Voltage

3 – 380V – 50HZ

3 – 380V – 50HZ

Customized Voltage

3 – 220V – 60HZ

3 – 220V – 60HZ

Motor Power

4.0KW

4.0KW

Working Pressure

63Mpa

70Mpa

Working Stroke

45mm

50mm

Tank Volume

36L

36L

Weight

101KG

130KG

Machine Spare Parts

For one size rebar, need one mould, one set mould has 2 pieces.

FAQ

1. What are the consumable spare parts?

Answer: mould, pressure tube.

2. What is the motor voltage?

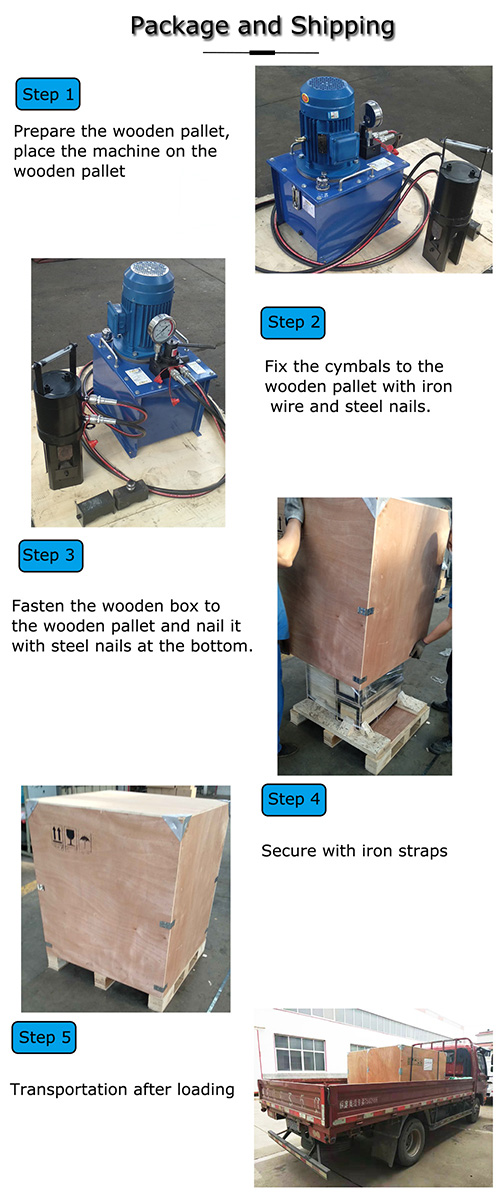

Answer: machine standard motor is 3-380V-50HZ. we also can make motor of 3-440V, 3-220V.Package and Shipping

The machine is packed with plywood case.

Customer Photos