Rebar Cold Extrusion Machine

-

Factory Direct Price Rebar Cold Extrusion Press Machine For Sale cold extrusion machine

JYJ-32 Model Rebar Cold Extrusion MachineMachine Function

It is used to extrusion coupler, in order to let coupler bite with rebar tightly.

Through squeezing force the rebar coupler become plastic deformation, then it can bite tightly with ribbed steel bars. It has hydraulic pumping station, electric motors, valves, fuel tank, electric motors, hydraulic pumps, valves, fuel tanks, and pressing die.

Machine Features

1. Ultra-high-pressure oil pump: powerful and vigorous, reducing working time.

2. Premium hydraulic pressure pliers: 60 MPa is easy to extrude, the extrusion result is good, and it is durable and not easy to form.

3. The pressure gauge shows: the pressure of the machine can be controlled at any time, and it is convenient to squeeze and release the pressure.

4. Dynamic pressure mould, constant pressure mould, reasonable design, excellent materials.Machine Parameters

Model

JYJ-32

JYJ-40

Crimp Size

Φ12 – Φ32mm

Φ12 – Φ40mm

Rated Voltage

3 – 380V – 50HZ

3 – 380V – 50HZ

Customized Voltage

3 – 220V – 60HZ

3 – 220V – 60HZ

Motor Power

4.0KW

4.0KW

Working Pressure

63Mpa

70Mpa

Working Stroke

45mm

50mm

Tank Volume

36L

36L

Weight

101KG

130KG

Machine Spare Parts

For one size rebar, need one mould, one set mould has 2 pieces.

FAQ

1. What are the consumable spare parts?

Answer: mould, pressure tube.

2. What is the motor voltage?

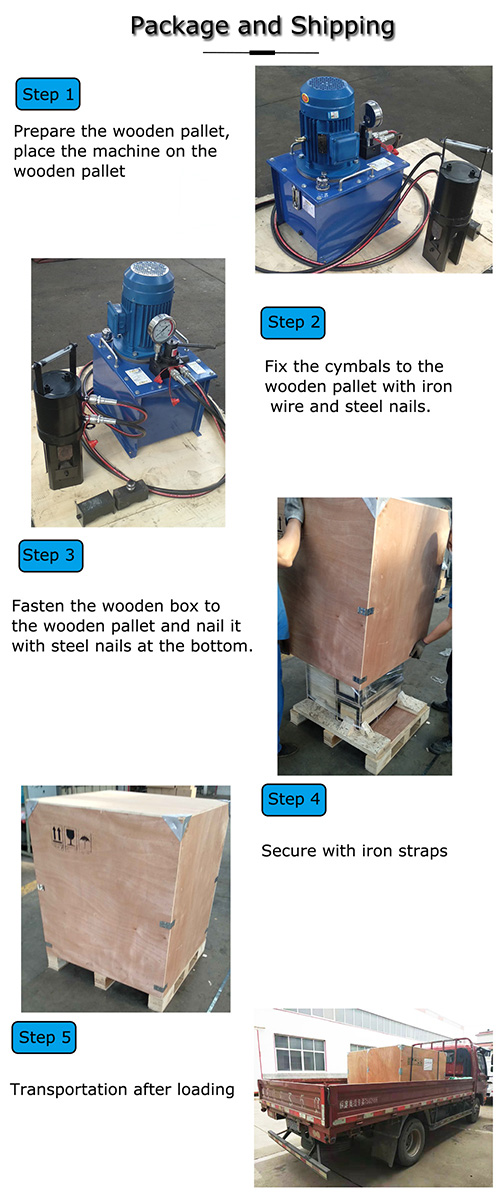

Answer: machine standard motor is 3-380V-50HZ. we also can make motor of 3-440V, 3-220V.Package and Shipping

The machine is packed with plywood case.

Customer Photos

-

construction tools portable electric steel rod rebar cold extrusion squeezing stamping machine

rebar cold forging machine hydraulic high pressure rebar steel cold extrusion machineCold extrusion connection is to be connected to both ends of steel bars are put on the sleeve, and then squeeze with squeeze clamp, the plastic sleeve deformation, the two reinforced together to form a tight connection of a mechanical connection.

Applicable scope: construction, reinforced concrete structure construction, high-rise frame construction, ordinary highway,

expressway, ordinary railway, high-speed railway, tunnel, bridge, airport construction, flood control dam, seismic shockproof building, marine breakwater dam.ModelJYJ-32Crimp size12-32mmVoltage3-380v 50hz or 3-220v 60hzMotor power4.0kwWorking pressure63MpaWorking storke45mmTank volume36LWeight62kgColorblueAdvantages

1. Stable connection process, convenient construction, easy operation.

2. Joint’s performance is reliable, quality is easy to check and control, and not affected by welding performance of rebar.

3. The construction is not affected by the weather

4. It is suitable for splicing of rebar in any position and direction (horizontal, vertical, surrounded by dense or diagonal).

5.The extrusion equipment is small volume, light weight, flexible operation, one person can move up and down by a hand to extrusion rebar conveniently. -

rebar cold forging machine hydraulic high pressure rebar steel cold extrusion machine

rebar cold forging machine hydraulic high pressure rebar steel cold extrusion machineCold extrusion connection is to be connected to both ends of steel bars are put on the sleeve, and then squeeze with squeeze clamp, the plastic sleeve deformation, the two reinforced together to form a tight connection of a mechanical connection.Applicable scope:construction, reinforced concrete structure construction, high-rise frame construction, ordinary highway,

expressway, ordinary railway, high-speed railway, tunnel, bridge, airport construction, flood control dam, seismic shockproof building, marine breakwater dam.Main technical Parameter as below:

Crimp size:12-32mmVoltage:3-380V 50HZ

Motor power:4.0kw

Working pressure: 63Mpa

Working stroke:45mm

Tank volume:36L

Weight:62kgAdvantages

1.Stable connection process, convenient construction, easy operation.

2. Joint’s performance is reliable, quality is easy to check and control, and not affected by welding performance of rebar.

3. The construction is not affected by the weather

4. It is suitable for splicing of rebar in any position and direction (horizontal, vertical, surrounded by dense or diagonal).

5. The extrusion equipment is small volume, light weight, flexible operation, one person can move up and down by a hand to extrusion rebar conveniently.