Rebar Upsetting Machine

-

Reinforcing steel rebar upsetting machine

16-40 model Double Cylinder Rebar Upsetting Forging Machine

Machine Function

16-40 model Double Cylinder Rebar Upsetting Forging machine is mainly used for upsetting 16-40 diameter rebar, increase the diameter of rebar, make rebar end enlarged, in order to make the effective section is larger than the original steel.

Such as for 25mm rebar, after upsetting, it is become 28mm.

Then you can use rebar thread rolling machine or rebar thread cutting machine to get rebar threads, connect with rebar.Machine Advantages

After upsetting by 16-40 model Double Cylinder Rebar Upsetting Forging machine, its tensile strength is larger than original rebar itself.

This machine is applicable to the reinforcement connection of national key projects with high requirements such as bridges and subways, and is not affected by environmental factors.

Machine Parameters

Model

16-32

16-40

Processing Range

Φ16 – Φ32mm

Φ16 – Φ40mm

Upsetting Length

3-5cm

3-5cm

Motor Power

7.5KW

11KW

Rated Voltage

3 – 380V – 50HZ or others

3 – 380V – 50HZ or others

Working Efficiency

3-5 seconds / piece

3-5 seconds / piece

Capacity of Tank

115L

165L

Oil Pump Flow

15L/min

15L/min

Hydraulic Oil Pump

31.5Mpa (10MCY 14-1B)

31.5Mpa (10MCY 14-1B)

Hydraulic Oil

68# Antiwear

68# Antiwear

Working Stroke of Cylinder

150mm

150mm

Weight

1000KG

1300KG

Dimension

1250*850*1650mm

1340*990*1800mm

Machine Spare Parts

For one size rebar, need one mould, one set mould has 2 pieces.

FAQ

Q1:What is the machine motor ?

A1:The machine motor is 3-380V-50HZ. but we also change it to 3-220V-60HZ, 3-415V-50HZ, 3-440V-60HZ, etc.

Q1: What is the rebar diameter after upsetting?

A1: After upsetting, the rebar diameter will become bigger. For instance, after upsetting the 25mm rebar will become 28mm. But if you have other special requirement, we also can customize mould for you. Q1: What is the machine spare parts?A1: The machine spare parts is mould. each size rebar needs one mould.

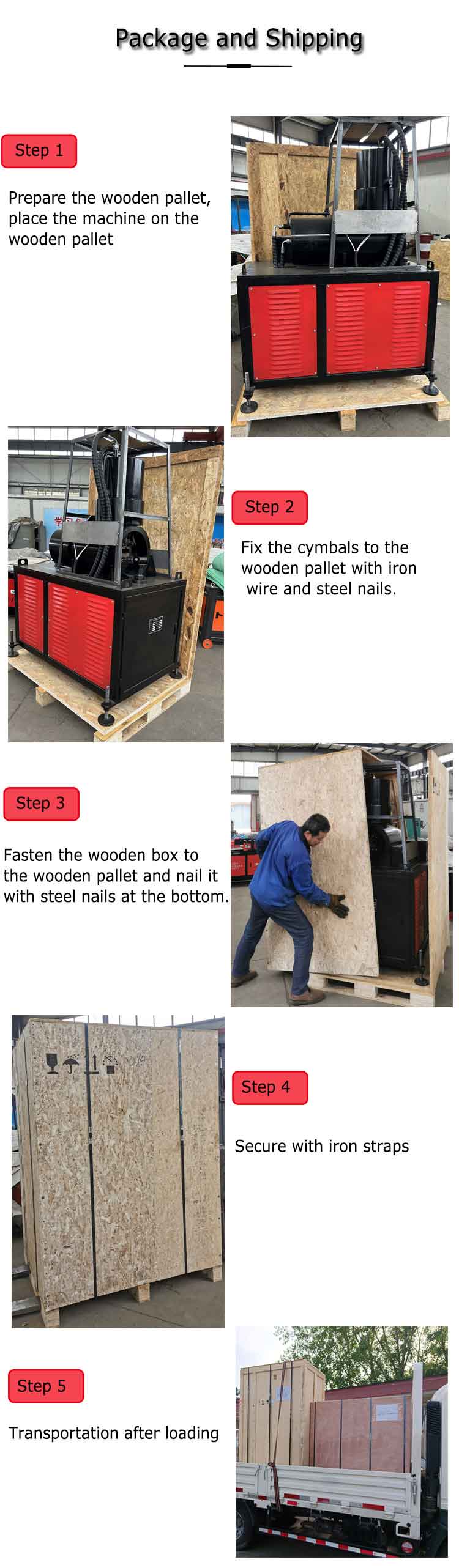

Package and Shipping

The machine is packed with plywood case.Customer Photos

-

rebar upsetting machine for construction

Rebar Forging Machine is a type of equipment used for enlarging ends of rebars.

16-32 model Double Cylinder Rebar Upsetting Forging Machine

Machine Function

16-32 model Double Cylinder Rebar Upsetting Forging machine is mainly used for upsetting 16-32 diameter rebar, increase the diameter of rebar, make rebar end enlarged, in order to make the effective section is larger than the original steel.

Such as for 25mm rebar, after upsetting, it is become 28mm.

Then you can use rebar thread rolling machine or rebar thread cutting machine to get rebar threads, connect with rebar.Machine Advantages

After upsetting by 16-32 model Double Cylinder Rebar Upsetting Forging machine, its tensile strength is larger than original rebar itself. This machine is applicable to the reinforcement connection of national key projects with high requirements such as bridges and subways, and is not affected by environmental factors.

Machine Parameters

Model

16-32

16-40

Processing Range

Φ16 – Φ32mm

Φ16 – Φ40mm

Upsetting Length

3-5cm

3-5cm

Motor Power

7.5KW

11KW

Rated Voltage

3 – 380V – 50HZ or others

3 – 380V – 50HZ or others

Working Efficiency

3-5 seconds / piece

3-5 seconds / piece

Capacity of Tank

115L

165L

Oil Pump Flow

15L/min

15L/min

Hydraulic Oil Pump

31.5Mpa (10MCY 14-1B)

31.5Mpa (10MCY 14-1B)

Hydraulic Oil

68# Antiwear

68# Antiwear

Working Stroke of Cylinder

150mm

150mm

Weight

1000KG

1300KG

Dimension

1250*850*1650mm

1340*990*1800mm

Machine Spare Parts

For one size rebar, need one mould, one set mould has 2 pieces.

FAQ

Q1:What is the machine motor ?

A1:The machine motor is 3-380V-50HZ. but we also change it to 3-220V-60HZ, 3-415V-50HZ, 3-440V-60HZ, etc.

Q1: What is the rebar diameter after upsetting?

A1: After upsetting, the rebar diameter will become bigger. For instance, after upsetting the 25mm rebar will become 28mm. But if you have other special requirement, we also can customize mould for you. Q1: What is the machine spare parts?

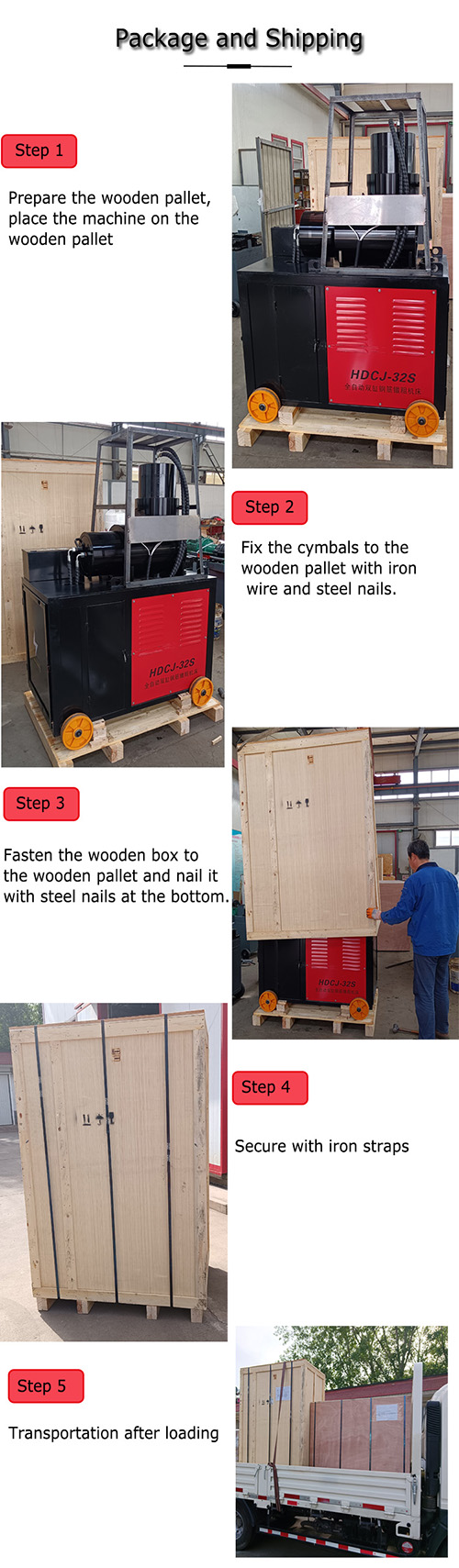

A1: The machine spare parts is mould. each size rebar needs one mould.Package and Shipping

The machine is packed with plywood case.Customer Photos